Five Plastics and Rubber LTL Shipping Tips

If you’re looking for a reliable LTL carrier that can ship your plastics and rubber materials, there are a number of factors to consider. Here are some important things you should know.

Get the latest news and updates on XPO

On-time service performance

If your plastics and rubber are utilized by customer production lines, your shipments are mission-critical to those operations — and you’ll need a high level of performance from your LTL carrier to meet their just-in-time (JIT) deadlines. Does the carrier you’re considering offer delivery options that support these deadlines? Will you have peace of mind knowing that your shipments are given high priority for on-time performance? Many LTL carriers offer a day-definite guaranteed delivery service, and some offer guaranteed delivery by noon, including a money-back guarantee if the shipment doesn’t meet the agreed transit time.

Another option for JIT deliveries is a time-date-critical service that ensures your shipments are delivered on the day and within the time window you select. This is particularly beneficial if you’re shipping to a warehouse or large distribution center with limited dock hours. And finally, you’ll want to choose an LTL carrier who provides proactive notifications, so you can track your shipment’s status in transit and upon arrival.

Damage-free shipments

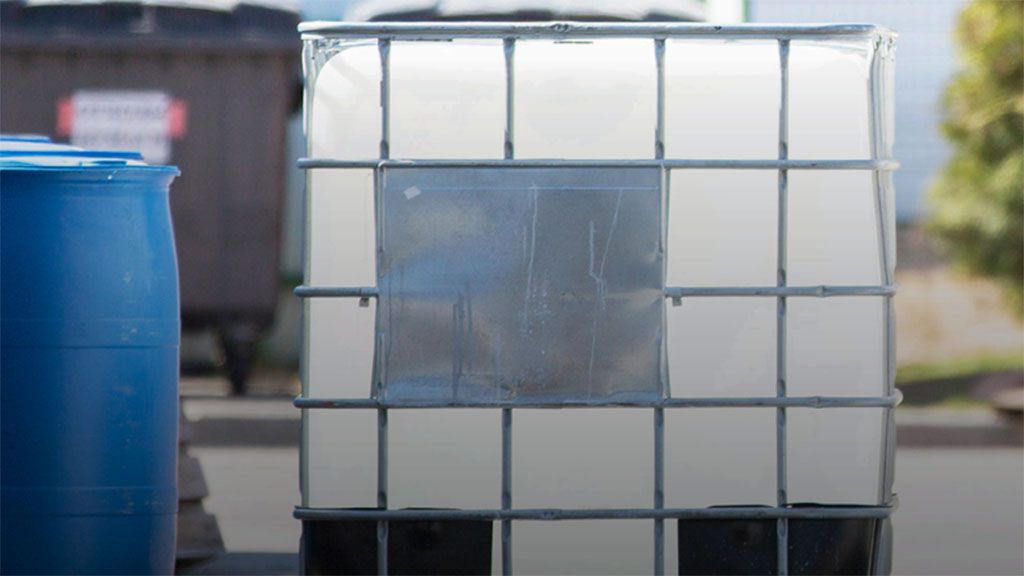

While plastic and rubber materials may not be considered fragile cargo, there are important reasons why this type of freight must stay intact throughout its transport. Be sure to package your freight in secure containers, and follow proper labeling and strapping requirements for plastics and rubber. These precautions, together with the carrier’s rigorous loading, unloading and handling protocols, will go a long way in preventing tears, punctures or crushed boxes, any of which can lead to spills. Spilled material may become comingled with others, or it could pick up debris from the trailer, compromising its integrity.

Some LTL carriers, like XPO, have a system of decking and strapping inside their trailers to secure the freight and limit shifting during transit. This is an important offering you should consider when evaluating carriers. By doing everything you can from the outset to reduce damages and exceptions with your plastics and rubber shipments, you could save time and money and help ensure on-time, intact deliveries, minimizing disruptions to your supply chain.

Cross-border shipping experience

Plastic and rubber goods are among the top U.S. exports to Canada and Mexico. If you ship cross-border between the United States, Canada and Mexico, you’ll need a carrier with experience and expert knowledge of customs processes. Some LTL carriers offer their own customs broker service, which can be very convenient if you’re an infrequent cross-border shipper. By using the carrier’s broker, you’ll know you’re meeting the customs documentation requirements, to minimize delays at the border. If you use your own broker, you’ll want to choose a carrier that has a track record of working well with brokers and communicates effectively with them.

Some other considerations are: How many border crossings does the carrier make? Where will your freight will cross, and is that the most efficient routing? Are the drivers experienced with the cross-border process? Will the customer service team assist you with your paperwork? Be sure to ask potential carriers about these services when evaluating them, to determine the most capable LTL company for you needs.

Flexible delivery options

As mentioned earlier, flexibility is important when selecting an LTL carrier to ship your plastic and rubber materials. Ask the carrier if they offer custom services — for example, inside delivery to locations without a dock. Construction site delivery is another custom service common to the plastic and rubber industries. You’ll want to develop a relationship with a carrier that has the capability to deliver to 100% of your customer sites.

Another valuable service that’s optional for shippers is freeze protection. Cold weather typically results in either very dry conditions or frozen precipitation. Very dry conditions can lead to brittle materials prone to breakage, while excess humidity and moisture can result in soggy cartons or packing materials that tear easily. The ability to customize the shipping will benefit your company and your customers.

Choose to ship with confidence

Choose an LTL carrier that you can feel confident about every time you ship — one you can rely on for on-time deliveries of just-in-time shipments, flexible service options to customize the shipping experience and cross-border expertise if your supply chain requires it. These are all key capabilities to consider. At XPO, the national coverage, competitive transit times and damage-free service we offer are an excellent value. Learn more about XPO by visiting xpo.com.

Further Reading